Some have said my post a few years back about how to calculate the dilution ratio of a pressure washer to use to figure soap use was too complected and I had directed people to an online calculator to do the math. Well I will attempt again to explain how to do all the math you would need to do to figure out how much soap to use for a job. At least to start with. Other factors may require tweaks from the calculated numbers.

So let's first start with your machine. Say it is a 5 GPM unit. We first need to check to be sure that is accurate. (You should continue to do this every few months to be sure it is staying where it should be.)

To check flow rate for 1 minute to see how many GPM your washer is currently putting out. Use a container that can measure gallons on the side and fill it for a straight 1 minute full open. This should be done with the tip you will be using on the end of your wand. Let us say you have a perfect machine and you get a full 5 gallons in that one minute.

Now take a gallon container that can measure by ounces on the side and fill it with water and drop in your downstream line (normally this would go straight into your concentrated soap or soap mix)

Turn on and draw the water from the container for 1 minute. This will show you have many ounces per minute you are drawing. Let us say you got 40 ounces.

Now we take those amounts that you got and run the numbers.

5 GPM is 128 (ounces in a gallon) x 5 = 640 in one minute.

Draw rate from your minute test (it was 40)

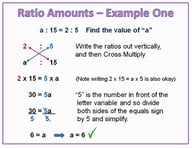

640/40 = 16. 15 parts water to 1 part chemical so you have a 1:15 ratio.

Next the soap you want to wash with has a starting recommended ratio to use of 1:35 with cold water so you need to know how much water are you going to add per gallon of your soap to make your mix for your machine to deliver the 1:35 ratio out the wand.

Now comes your fraction lesson.

You need to find X; 1/15 = X/35. So divide 15 into 35 and you get 2.3.

cross multiplication 1x35=35/15=2.3

So you will add 1.3 gallons of water to the 1 gallon of soap concentrate so you end up with a total volume of 2.3 gallons this is what you will drop your hose into to draw the soap to get the 1:35 ratio.

So what if your soap reservoir can only hold one gallon?

More math! You turn the gallons into ounces 2.3 gallons is 294.4 ounces.

294.4/128 = 128 (the single gallon of your reservoir)/X

Cross multiplication again. 128x128= 16384/294.4=55.65 ounces.

That is how much concentrated soap you will put into the gallon reservoir topped off with water to still give you the 1:35 ratio out the wand.

So you start to wash and it is cold outside, the surface is dirtier than you thought, etc. and the soap is just not cutting it. I always suggest going up in 10% increments at a time until the soap is working. So for this mix I would add another 5-6 ounces of soap to the reservoir once their is room.

Or if the opposite is happening and you find that the soap is cleaning gang busters then increase the amount of added water by 10% at a time until it is not as effective. So for this gallon reservoir that would mean to add 13 ounces of water, when the level got low enough, and see how that was cleaning.

Once your soap has reached it's effectiveness, using a higher concentration of it is just wasting soap, not increasing the effectiveness of your cleaning so try to not waste soap.

And remember using warmer water will reduce the amount of soap you will need, since the heat increases the efficiency of the soap up to half as much.

If you have any questions about ratio calculations just give me a call. 800-762-7911.