How Hard Water Effects Pressure Washing

For most of the country hard water is a way of life, the only difference may be in the degree that you have it. So how does hard water effect pressure washing and what can be done about it?

First lets us discuss where hard water is found and where it comes from.

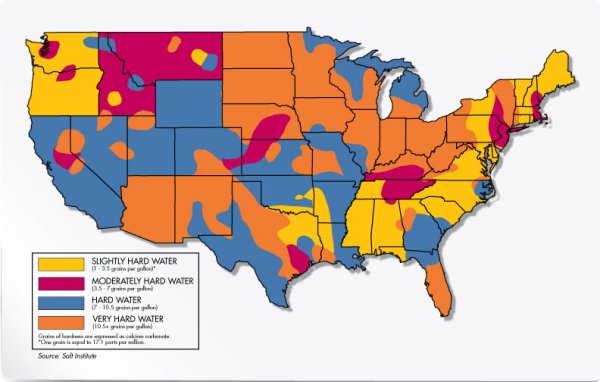

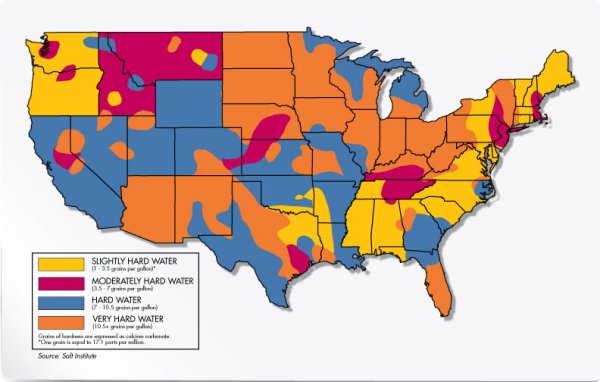

Water hardness is rated by GPG - grains per gallon, and hard water, higher than 1 GPG includes 85% of the country. The amount of hardness will vary from slight to extreme, see map.

Hardness Levels

- Soft water – less than 1 grain per gallon

- Slightly hard – 1 to 3.5 grains per gallon

- Moderately hard – 3.5 to 7 grains per gallon

- Hard – 7 to 10.5 grains per gallon

- Very hard – 10.5 and higher grains per gallon

Rain water dissolves minerals present in rocks as it passes though the ground down to the water table, aquifers and wells. Carbon dioxide being heavier than air also combines with rain water underground and helps convert the carbonates of calcium and magnesium into bicarbonates. These bicarbonates being soluble in water cause hardness. These bicarbonate salts exist in the form of positive and negative ions which can be used, as you will see later, in ways to help incapacitate or remove them by certain methods, one being ion replacement.

Disadvantages of hard water

For the pressure washing contractor the first effect of hard water is on the soaps and detergents. Because soap and detergents have an ionic nature, when they dissolve in hard water, each soap molecule reacts with any calcium ions, limits the formation of lather and instead forms precipitates or scum. This scum essentially renders the detergent ineffective, so much more soap is needed to clean if used with hard water.

The second major problem with hard water is that when it is heated, it will deposit solid calcium carbonate or lime scale. Scale is a poor heat conductor and in a hot water pressure washers scale insulates water from the coils heat source. For many pressure washers a hot water machine is a necessary time saver, since heat increases the effectiveness of soap and helps break down and dissolve the contaminates they are trying to remove for their customers. But the scale produced in their machines when using hard water will very quickly start to reduce the machines effectiveness to heat and maintain hot water as well as restrict water flow in the other pressure washing equipment, even to the point of changing the flow rate Gallons per minute or PSI that the machine should be producing. As flow is restricted it places a heavier strain on the pumps motor which can cause early wear and failure.

Water Softeners

To reduce the negative effects of hard water, many ways have been developed to remove hardness. These techniques range from adding softening chemicals, to either the soaps, the water or both, in order to avoid having to use larger quantities of detergent and stop lime scale. Portable filters can be used to filter water running through the machine to change the ions to prevent scale build-up on the heating element. Water softeners work using a technique called ion exchange, whereby calcium and magnesium ions are replaced by sodium ions, which do not cause hardness. Even separate machines containing magnets are now being used to alter the molecules action in the water just before entering the machine to inhibit scale build up with out using chemicals at all, just electricity.

You may already be using softeners

Soap manufactures are very much aware of this problem and many add softeners to their chemical mixes without the customers not even knowing it. These softening benefits may be communicated in the detergents description with phrases such as "superior ingredients", "great suds action", "works well in hard water" "cleans well in cold water". Just like car wash patrons that are not aware that they are probably getting extra sheeting and quick drying chemicals added to their final rinse whether or not they are paying extra for them, just because the car wash owner wants you to be happy with a dry car and come back again. And since these chemicals are not hazardous they are not mandated to be listed on a MSDS or reported to consumers.

Local water departments may also be adding softeners to the water supply that you are not aware of. In known hard water areas ground waters may be treated by lime softening, as are many hard surface waters, or by ion exchange softening, in which calcium and magnesium ions are exchanged for sodium ions as the water passes through a bed of ion-exchange resin. The only way to know how hard your local water is, is to have it tested or read up on it in the latest water departments federal reports. Most are easy to find or copies supplied when requested as long as you live or own a business in their jurisdiction.

Costs to create a balance

You as the pressure washing professional must gather information and then weigh the options available to find the most cost effective way to combat hard water and it effects on your equipment and bottom line.

Here are some numbers we have gathered from speaking with owners of pressure washing equipment businesses that also handle pressure washing repair.

The pressure washer part most effected: the hot water coil, second is the pump itself.

The time and cost of de-scaling a coil; time 4 hours, cost average $260.

Cost of replacing a coil $800 - $1,800 depending on size and brand of machine.

Infrequency of run time is a larger factor in regards to scale build up compared to the length of run time. In other words you can't just say you should clean your coils after every 100 hours of run time. A machine that was run 100 hours in 5 hour long sessions all in one month will have much less scale build up than a machine that ran 100 hours used in only 1-2 hour sessions that covered a 6 month long time period. It seems one point is the frequency of heating and cooling, along with the length of time that water circulates through the machine, that can play a role in build up. For instance here is a photo of the inside of a home owners pump that was used only twice but three months apart and when the owner pulled it out again 6 months later was having trouble with stuck valves.

You can work from the front of the problem and buy soaps with added softeners, buy additional softeners to add to your chemical mix or water tanks, attach filters or electromagnet systems as water comes into your machines or on the back side just periodically use coil cleaners or pay to flush the scale from out of your machine to deal with hard water. Any way you go, costs will occur. It is just up to you to evaluate your options and find the most cost effective solution. Because the only other recourse is to ignore the facts about hard water and pay for it over and over again in mechanical repairs and replacement costs.

Soap Warehouse has just added a new product to our line called Dyn-O-Coil. This is a additive to use in your mix water or any soap product that will prevent or even remove scale deposits over time. This product is in addition to our So-Soft water softener and our Non-Acid Coil Cleaner that we introduced earlier this year. Call to order 1-800-762-7911 or view pricing on line in our catalog.

Mineral Scale Preventer System. Many contractors complain about how their hot water machines get fouled and had problems stemming from hard water issues. So with that in mind this new product will inhibit scale crystal formation and even remove existing scale on coils, in a pump, on valves etc. with no harm to the machines parts.

Mineral Scale Preventer System. Many contractors complain about how their hot water machines get fouled and had problems stemming from hard water issues. So with that in mind this new product will inhibit scale crystal formation and even remove existing scale on coils, in a pump, on valves etc. with no harm to the machines parts.