First it is important to mix the component packages in the order they are labeled and it states in the directions.

For the most part they are very simple instructions but by not adding a part in the correct order you can either make a small difference, all the way up to making things dangerous.

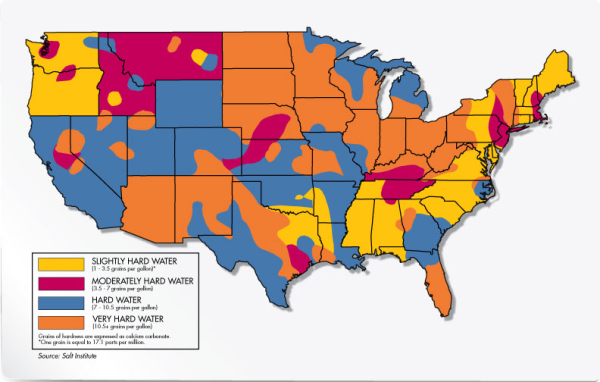

If a kit comes in A, B and C and it clearly states put A in then add water, then please do that. I know some might like to start filling the drum before they pour in the first powder but there is a reason. First is to be sure the ingredients in the A component dissolve well. For instance it is much harder to mix a powdered chocolate drink mix into a full glass of cold milk then it is to put the powder in first, pour the milk in and then stir. Same principle. And make sure the water is not too cold! Even tap water in some parts of the country and during many times of the year may be colder then needed for proper mixing. Directions say to use "Tepid water". Tepid only means the same temp as your skin or around 98 degrees. If a powder is not disolving, try adding luke warm tap water, but if your water is cold you will need to add some hot water, say a gallon to every 4-5 gallons of tap water, that you are adding to the mixing drum (prior to pouring it in). In other words, have a 5 gallon pail that you are using to add water that you mix the hot and cold water together before pouring it into the drum. The reason being hot water increases chemical reaction and may become hazardous if hot water is used.

Next if it says to use 45 gallons of water, then add 45 gallons, not 20 or even 40 but 45. If the amount of water is too small and you add in other ingredients early, you might cause a reaction due to having too high of a concentration of the raw chemicals together.

Next, always add the second "B", third "C" and so on number of ingredients slowly to your mixture. One so that you do not splash chemicals back on to yourself or into your eyes (Always wear protective gear when mixing) and second so that you have time to properly stir and mix the solution for complete integration.

I know some people like to put all the powders together and then add all the liquids or put powders in after all the liquids are in the drum but this can cause dangerous results. Some of the chemical powdered ingredients should not be put together, or they would have come packaged that way. Or one powder may need to be added only at the very end when you have the most amount of water in the drum because it may produce a stronger reaction if added too soon or when less water is present.

When pouring the liquid components into a partial solution, add slowly and stop once or twice to mix well so the new liquid does not fall straight down to the bottom of the drum, since it will be denser than the solution already in the drum. Once you have emptied all the liquid that will easily pour out be sure to scrape the walls of the pail off to get all of the liquid out. A kit is designed to use all of the parts for the correct results. If it is too difficult you can just add a small amount of warm water, say 1/2 gallon, and with the lid back on and tightly closed, slosh the water around in the pail to dissolve the remaining residue into a thin enough liquid to be pored into the drum with the rest of the mixed solution.

Once you have finished adding ingredients and mixing make sure you top off to the proper level. If you have a product where one drum will make two, be sure you have thoroughly mixed the entire 55 gallons, transfer half of the drum (27.5 gallons) to a second drum and then fill both back up to the 55 gallon level. If you wait for even a few hours or a day before transferring make sure you thoroughly remix the first drum before you start to pump out the 27.5 gallons in case you have settling of ingredients. This can sometimes be the reason why one drum seems to work much better than the other because you got an uneven amount of active product ingredients in each drum.

This is also the reason you mix any super concentrated product all at once and DO NOT just pump out 1 gallon of a 5 gallon mixture and make only 11 gallons of product at a time. These super concentrated pails are designed to be completely mixed because of how the ingredients will settle out or layer in the pail. if you try to mix partial batches, no two mixtures will be or will work the same.

Same can be said when you mix a drum and then only pump out small amounts at a time. You should always remix at least for a few minutes to reintegrate the solution. Some products settle out more than others and temperature can be a large factor in this. If you store your chemicals out in an unheated building or area, products will have the tendency to settle more quickly than if left at 70-75 degree average room temp. Try to pump from the center of a just re-mixed barrel to insure you will get the same product gallon after gallon. If you only pump from the bottom your product may be too strong in the beginning and too weak at the end. Same with only pumping off the top. You may not be getting a proper mix of active ingredients to give you the best performance.

Our products are all produced with a very short pre-ship storage time. We try to have product made from just a few weeks to only a few days before they are ordered and ship out. This way they are very fresh and have a long storage life, for most at least two years if stored properly. This way you can buy a large volume of product to save money and shipping costs and even if you do not use all of it by the end of your wash season, you can be sure it will still work when you mix it and use it at the beginning of the next season. With this said it is important that if product has not been kept in the most ideal conditions that when it is mixed you can take additional steps to try and make it still work for you. We have had customers call that have let product freeze or nearly freeze, get wet or exposed to moisture that the powders become solid, etc. Many of these problems can be addressed with sometimes no ill effects to the end mixed product.

If you have a liquid component that has frozen or has gotten extremely cold, you must raise its temperature high enough to allow it to pour but not too high to destroy the products chemical integrity. We suggest that you get a larger container than the 5 or 6 gallon pail the liquid is in, fill it with warm water and place the pail into it. Do NOT use HOT water, this way the temp is brought up slowly. It may take more than one dunking application to have this work. But do not do what one customer did. He broke open the pail, dumped the frozen rock of liquid into an open 55 gallon drum and then poured boiling water on it trying to melt the ice block of concentrated product. He ended up not getting all the product dissolved before he added all the water to make the 55 gallons and then it did not work properly even days later once he got all the settled melted bits mixed.

Now sometimes if stored for a long time the bagged powder mixes can compress and get firm, but they should not turn to solid blocks. Only if they are exposed to moisture, heat and sit for long periods would this ever happen. If it does it may still be usable but you must allow the block to soak, break up and dissolve in a much smaller amount of water than normally used for mixing. Again using warm water, not hot, add the solid powder to about twice the amount of water by weight than you have of the powder. So if you have 5 lbs of solid powder place it in 10 gallons of water and wait for it to completely break down before mixing it with the other ingredients in the proper order with the other ingredients and the proper amount of additional water.

I hope this has been helpful and as always, if you have any questions please give us a call. 1-800-SOAP-911

.jpg?width=257&height=184&name=c--documents_and_settings-dan_kidd-my_documents-my_pictures-imotion_items_and_frames-drumkitframe_(small).jpg)